TECHNOLOGIES

We go beyond standards to achieve

new levels of innovation

MF Catenificio Frigerio is always on the lookout for technological solutions that combine production and quality requirements. With this approach innovative ideas have come to life, such as the Solid Zinc chain treatment, the DAMS chain design system and the Chain Life Simulator product development system: all concrete examples of how innovation is applied across the board at company level.

TECHNOLOGIES

We go beyond standards to achieve

new levels of innovation

optimise, improve, supervise

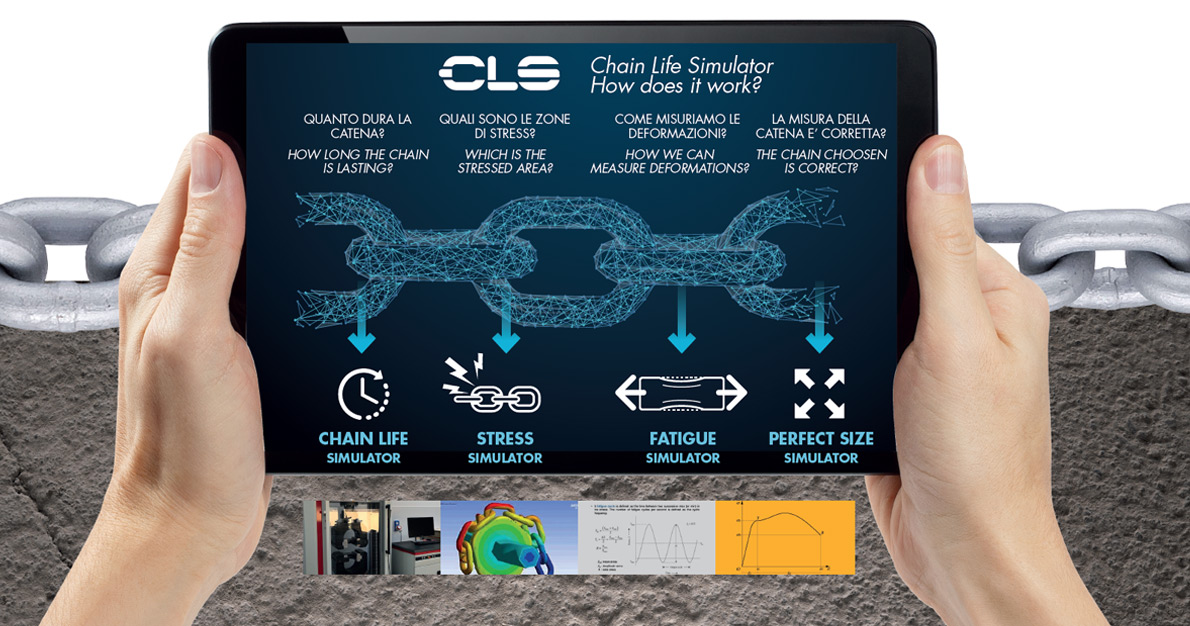

CLS stands for CHAIN LIFE SIMULATOR.

In the common use of a steel chain in a machine such as a conveyor device, the chain is subjected to various forces depending on the installation and design of the system, the speed and the purpose of the machine.

In the common use of a steel chain in a machine such as a conveyor device, the chain is subjected to various forces depending on the installation and design of the system, the speed and the transport purpose. In many cases these forces are unknown, in some other cases calculated.

Providing the correct chain to withstand these forces over time is not easy to determine, especially in the case of a lack of information.

not easy to determine, especially when historical information is lacking.

CLS is a simulation model that we can use to determine:

- Geometrical and mechanical characteristics of the chain to be used for validation.

- Deformation and stress yield over time due to wear.

- Fatigue resistance cycles.

- Force stress points on the links and analysis of the risk of breakage.

Dams

Downsizing effect

With DAMS, MF introduces a new category of chains and related accessories for marine construction of floating docks, mooring of boats with traps, anchoring of buoys and anchoring of boats.

The system is designed especially for the construction and maintenance of marinas and city harbours and buoy fields. DAMS mooring brings significant cost benefits during the product life cycle for all players involved in maritime mooring, from end users to project engineers, from marina owners and infrastructure managers to operators for initial installation and subsequent maintenance.

DAMS enhances safety in case of natural disaster events by increasing overall wind and wave resistance, while providing more comfortable anchoring for boats and ships.

Solid Zinc

MF's recipe for zero corrosion

In addition to the traditional hot-dip galvanising, which guarantees a thickness of 80 microns of zinc, MF has applied a new specific treatment called SOLID ZINC, which gives the chain a further 25% increase in corrosion resistance and an aesthetically pleasing and homogeneous chromatic appearance with a clear improvement in the quality of the first two layers of the zinc-steel alloy.